Method of thread locking and sealing

The anaerobic thread locking sealant can fill the thread meshing gap and increase the meshing area to obtain reliable locking. The cured glue has excellent corrosion resistance to ensure no omissions. Lockable and sealed thread in the process of use, due to vibration, impact, high temperature and medium corrosion and other factors caused by loosening and leakage.

l. Clean the screw surface of bolts and nuts with sealing multi-functional cleaning agent. New bolts on the assembly line need not be cleaned.

2, according to the need to seal the thread of the correct selection of the appropriate grade of thread locking sealant. Refer to the "Usage and Selection Guide" and "Key Performance Indicators" to select.

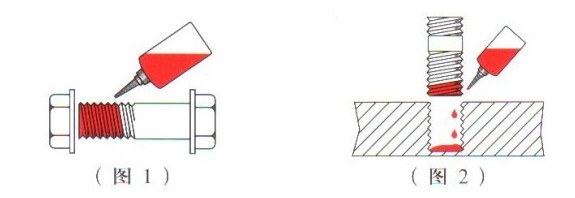

3. Drop a few drops of thread locking sealant to the point where the bolt engages with the nut, as shown in Figure 1.

4. For blind hole screws, the sealing Shen1271 thread locking sealant should also be dropped into the blind hole, as shown in Figure 2.

5. Screw on the nut and tighten it to the specified torque.

6, for the parts that have been assembled, the sealing god 1290 thread locking sealant can be dropped into the engagement of bolts and nuts.

Removal and reassembly of threads

(1) Under normal circumstances, it can be disassembled directly with an ordinary wrench.

(2) The thread or thread with a large diameter (above M26) that is locked with locking glue is difficult to disassemble by ordinary methods, and it is necessary to disassemble it hot after heating the glue part to 230 ° C.

(3) When assembling again, the original adhesive layer should be cleaned and cleaned with a multi-functional cleaning agent before gluing.

Matters needing attention

Anaerobic rubber thread locking sealant can not be used to seal pure oxygen or oxygen rich systems, nor can it be used for strong oxidizing agents (such as chlorine gas, etc.) lines.

In order to better serve you, you can call for advice: 18608671817 QQ879830916