Seal God · anaerobic glue specific construction process

Anaerobic adhesive refers to a series of components with anaerobic curing characteristics that can play the role of bonding, fixing and sealing. Anaerobic adhesive for short.

anaerobe (anaerobe) is also known as anaerobe, anaerobe, thread glue, mechanical glue. It does not solidify when in contact with oxygen or air. Once isolated from the air, it quickly polymerizes into a solid cross-linked polymer. "Anaerobic"; means that the glue does not require oxygen when used.

Special term for anaerobic glue

1.. Strength: The unit of strength is N.m, which is a torsion strength, is an international common unit, which is an indicator for detecting the locking strength of anaerobic glue, which is divided into failure moment and disassembly moment.

2. Avoid pollution: Because anaerobic rubber encounters metal ions, it is easy to form polymerization reaction, which affects the storage period, so it must avoid pollution when storing. During the production process, anaerobic glue can not come into contact with metal products, otherwise it will affect the storage period.

3 Inert metal: The so-called inert metal is inactive metal (such as aluminum, stainless steel, galvanized, chrome), anaerobic adhesive used on this metal, curing speed is very slow, need to use accelerators.

4. Accelerator: The so-called accelerator is an auxiliary agent that can accelerate the curing of anaerobic glue, which is generally used in low temperatures or inert metals.

200 thread sealant

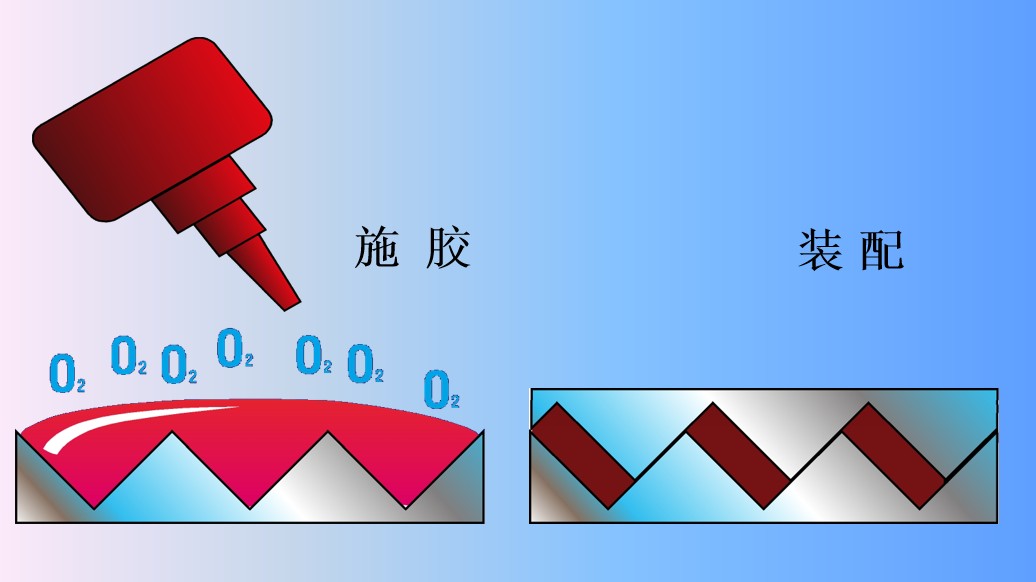

After the glue is filled with all the voids at the mesh of the thread, it solidifies due to hypoxia and forms an insoluble and insoluble polymer. Fill the whole thread gap, so that the contact part of the thread is difficult to produce relative displacement, which can effectively prevent the micro slip under the action of external force and loosen the characteristics of the plane sealing with anaerobic glue

(1) The bonding strength can be adjusted into high, medium and low strength

Thread locking adhesive is divided into low, medium and general average disassembly torque

(Release torque) less than 5N.m is low strength, and the average disassembly torque is

The strength between 5 and 15N.m is medium, and the average disassembly torque is 15N.m

The above is.

(2) To have the right viscosity

The gap of thread meshing has a great influence on the bonding strength. Generally speaking, the gap is small and the bonding strength is high. Low viscosity glue is suitable for small gaps. If it is used for the workpiece with a large gap, in order to avoid the loss of glue, the glue with large viscosity can be selected.

500 pipe thread sealant

(1) Low bonding strength

For sealing applications, bond strength is no longer the main test indicator, in order to facilitate disassembly and protection of threads, torque strength should be controlled low, pull out torque should be close to zero.

(2) High viscosity

In order to prevent flowing, most of the glue has thixotropy, adding an appropriate amount of thickener, can improve the viscosity, improve its interstitial and immediate sealing ability.

(3) The curing speed should not be too fast

In order to meet the need for minor adjustments in the position of some pipe joints during the final assembly, it is often required that the pipe thread position can be slightly moved within a few hours after gluing to still maintain the seal. Therefore, the curing time of some special anaerobic adhesives even exceeds 72h.

600 cylinder holding agent

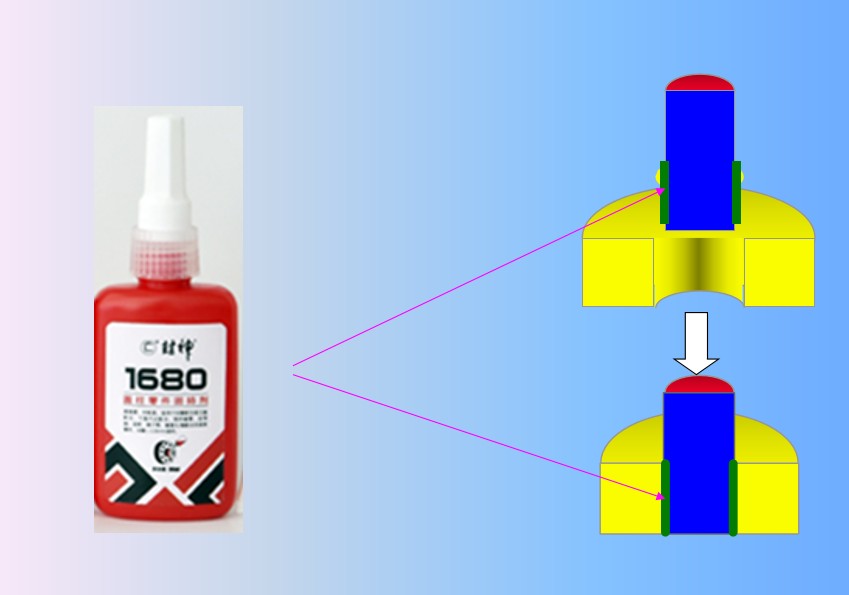

When the parts are assembled, the anaerobic adhesive can penetrate into all the cracks, make the workpiece 100% contact after curing, achieve adhesion and solid holding, and have the role of anti-loosening and sealing, and can change the workpiece assembly from press fit to smooth fit, processing accuracy and finish can be appropriately reduced, and also eliminate the deformation caused by press fitting, improving the assembly accuracy. It kills many birds with one stone. For bearings and bushings with small interference fit, it is especially suitable to use anaerobic adhesive. This is even more significant for thin-walled, high-speed, precision bearings, and helps reduce noise and vibration.

1) To have a certain bonding strength

The adhesive sleeve (embedded) connector must withstand a certain external force, so the adhesive shear strength as an anaerobic adhesive for bonding should generally be greater than 15MPa. For bearings, bushings and other light-load frequently changed parts of the adhesive can be selected with lower strength, so as to facilitate disassembly.

(2) To have the right viscosity

The gap of the sleeve (embedded) joint has a great influence on the bonding strength. Generally speaking, the gap is small and the bonding strength is high. The viscosity of the adhesive is generally low, such as 50 ~ 100mPa•s, to meet the needs of small gaps. If it is used for sleeve (embedded) joints with large gaps, in order to avoid the loss of glue, the viscosity of the glue can be selected.

Curing conditions of anaerobic adhesive

oxygen-free

Active substrate - Metal

copper

iron

Steel, etc.

Different environments and conditions will affect the curing of anaerobic adhesive.

Factors influencing the curing speed of anaerobic adhesive

Adhesive material

Filling gap

temperature

accelerator

Surface cleanliness