Neutral silicone sealant specific use method

It is impossible to fit between the two planes due to the influence of plane roughness, finish, knife marks and other factors, resulting in leakage. Solid gasket aging due to temperature, pressure, medium and mechanical force, so that the seal failure. The use of plane sealant can compensate for the roughness of the surface of the parts, so that the two planes contact, improve the structural rigidity and bearing capacity, long-term use without leakage.

(1) Sealing of the joint surface and flange surface of the box

For the joint surface with sealing gap less than 0.5mm, seal with anaerobic adhesive.

(1) First remove the residual liner, adhesive layer and oil and other impurities of the sealing surface, but do not polish to avoid affecting the flatness of the sealing surface.

(2) Clean the mating surface with cleaning agent.

(3) Apply "Fengshen" 1515 on one of the sealing surfaces to form a closed rubber ring, and the screw hole must be coated around the glue.

(4) It can be assembled at any time within 45 minutes after gluing. Align and close, tighten screws to avoid misalignment.

(5) After curing at normal temperature (25℃) for 3 hours, the pressure of more than 10 MPa can be sealed.

(2) Sealing of large gap stamping parts

For planes with sealing gaps greater than 0.5mm, such as stamping parts, it is difficult to cure with anaerobic plane sealants. At this time, the silicone rubber plane sealant can form a high elastic medium strength silicone rubber gasket.

(1) First remove the original residual liner, clean up the oil, dust and other impurities on the surface to be sealed and dry it;

(2) Clean the mating surface to be sealed with cleaning agent;

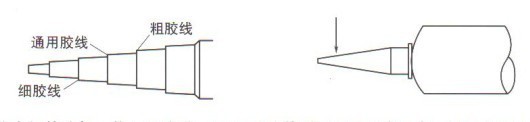

(3) According to the width of the sealing surface and the sealing gap to determine the diameter of the extrusion strip, select the size of the glue nozzle, cut off with a knife, as shown in the following figure. The amount of glue should not be much, and the amount of glue outside the extrusion sealing surface should be reduced as far as possible;

(4) Remove the rubber cap of the aluminum tube and install the glue nozzle. 300ml silicone tube need to cut off the head with a knife, and then screw on the glue nozzle;

(5) Apply "Fengshen" 1587 or 1596 or 1598 on one of the sealing surfaces to form a continuous sealing rubber ring, and glue must be applied around the screw hole;

(6) Close the assembly within 10 minutes to remove the excess glue that is extruded to the outside;

(7) Curing time depends on temperature, humidity and gap, generally 24 hours curing.

(3) Production of gasket coating

(1) When it is difficult to meet the sealing requirements with rubber under certain working conditions, or when it is difficult to cancel the gasket due to gap requirements, anaerobic rubber or silicone rubber can be applied on both sides of the gasket.

(2) Sizing can be applied to both sides of the sealing surface, or to both sides of the gasket, which need to be applied into a continuous closed adhesive strip.

(3) Assembly according to the conventional method, but please note: the anaerobic rubber flat sealant can be assembled within 45 minutes, and the silicone rubber flat sealant must be assembled within 10 minutes.